“Full Service Mentality” is a key driver to our concept of Customer Satisfaction. Our activity in the field of procurement has been accordingly engineered to target that goal with a threefold offer. On the one hand, we focus on the core of our business, that is, castings. Additionally, we can provide patterns, machining and forgings, to ensure that all potential requirements of our customers are met.

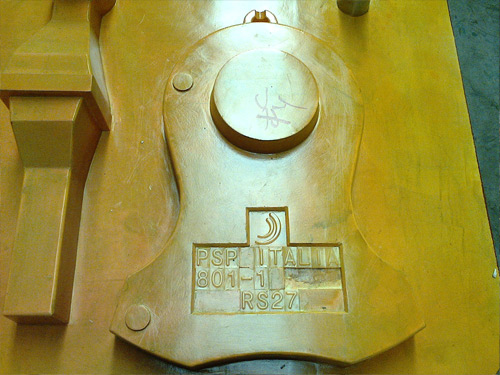

casting

We can handle several different kinds of productions. Our range of casting products include:

- grey iron castings

- nodular iron castings

- steel castings

- stainless steel castings

- nonferrous metal castings

- investment castings

- fabrications

patterns

forgings

We have recently widened our capabilities by adding forgings to our already expanding range of products. We are able to supply forgings in Carbon steel, alloy steel, stainless steel, duplex steel according to the international standards and the Customer’s specific requirements.

product related services

Machining

Through our sub-contractual partners we are able to perform the final machining of the castings directly in the production area, thereby adding value to the production and minimizing the risk of quality-related claims after deliveries have taken place.

All our partner workshops operate state-of-the-art, technologically up-to-date equipment which can meet every customer needs in terms of machining.

Quality Control

Our pool of suppliers is composed by leading companies with a global profile, and are directly qualified by our personnel. Among the criteria that factor in the selection of every new partner foundry are their compliance with international quality standards, the quality certifications they hold (among which Det Norske Veritas, ISO 9001, Lloyd’s Register American Bureau of Shipping, Germanischer Lloyd), their capability to handle productions in accordance with Western European quality requirements.