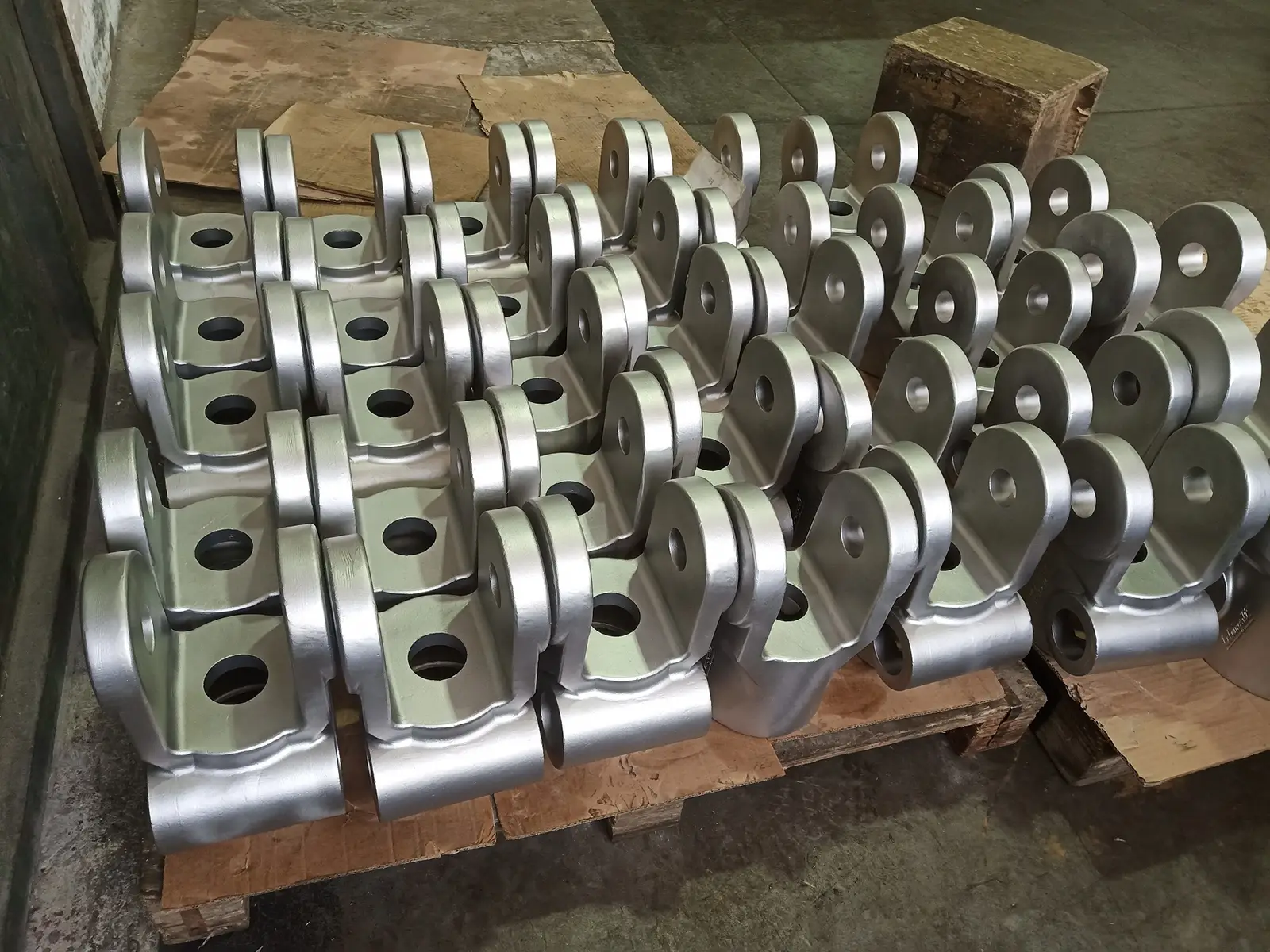

PRECISION CASTINGS

Precision castings for complex geometries and tight tolerances

PSP Italia’s precision castings are the ideal solution for components requiring complex shapes, high surface quality, and very tight dimensional tolerances. Using investment casting (lost-wax casting) technology, we produce parts with sophisticated geometries and excellent surface finishes, often eliminating the need for extensive machining.

This technology is particularly suited for small to medium production runs, prototypes, and high-value components. Castings can be supplied in cast iron, carbon steel, stainless steel, and special alloys, either as-cast or machined, with options for heat and surface treatments, non-destructive testing (UT, MT, PT), and EN 10204 3.1 certification.

Key features

- High dimensional accuracy and superior surface quality

- Production of complex and detailed geometries

- Significant reduction of machining operations

- Ideal for small and medium series and high-complexity components

Technical specifications

- Casting weight: from a few grams up to approx. 50 kg

- Dimensional tolerances: according to VDG P690

- Material certification: EN 10204 3.1

- Quality inspections: UT, MT, PT, spectrometry, mechanical testing

- Additional options: CNC machining, heat and surface treatments, marking, full technical documentation

Main applications

- Components for valves, pumps, and turbines

- Complex parts for the energy and oil & gas sectors

- Structural elements for industrial machinery

- Precision components for high-performance applications

PSP Italia works closely with its customers from the design phase to optimize geometry, wall thicknesses, and feeding systems, ensuring high performance and consistent quality in every casting.